|

|

Post by Mofo on Oct 20, 2012 21:37:52 GMT -7

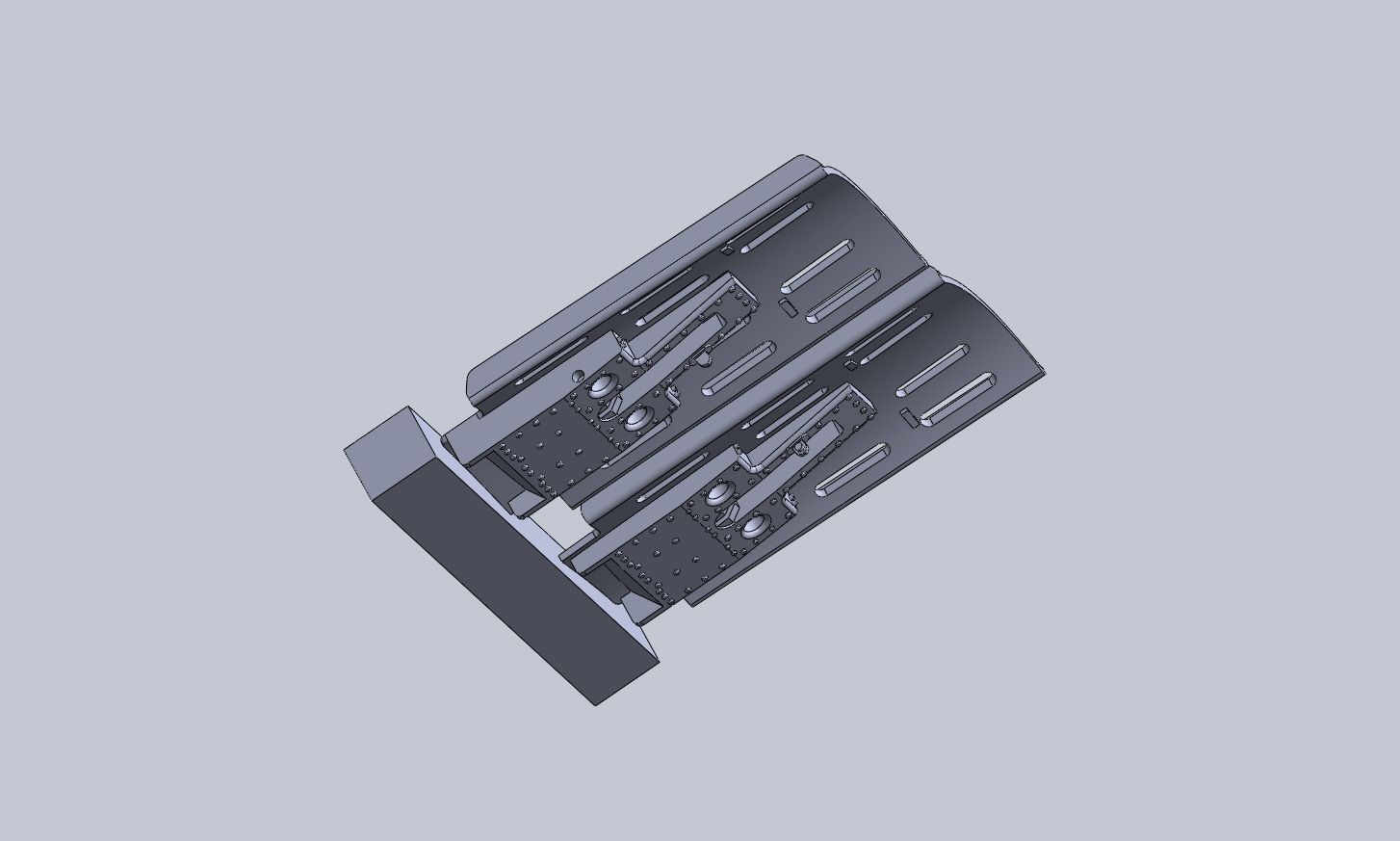

Had one of the first snowfalls of the year. Listened to some podcasts. Did this:  (airbrakes for the *just* released Kinetic T-45 - the kit parts are thick, missing the flanges, and have some dimensional nits) With a bit of luck, actual production can be done by printing - I don't think it would castable in resin. (.3mm thick, and details on every surface). |

|

|

|

Post by regulus on Oct 23, 2012 11:40:18 GMT -7

Yes, that's very nice. I thought at one time they simply had to offer the outside part as a PE piece.

If it can be printed, it can usually be cast.

Lee

|

|

|

|

Post by kyrre on Oct 23, 2012 15:42:56 GMT -7

I want new airbrakes for the Hobby Boss F-84's in 32nd scale.

K

|

|

|

|

Post by mrcreosote on Oct 25, 2012 5:36:29 GMT -7

Myself. I want new airbrakes for the Hobby Boss F-84's in 32nd scale. K |

|

|

|

Post by kyrre on Oct 25, 2012 6:49:16 GMT -7

Okay.

I want new airbrakes for the Hobby Boss F-84's in 32nd scale myself.

|

|

|

|

Post by gnat on Oct 25, 2012 8:38:53 GMT -7

How much does a part like that cost to be "Printed"

Gnat

|

|

|

|

Post by Mofo on Oct 26, 2012 10:47:18 GMT -7

Short answer: it depends. There are a bunch of different companies that print stuff. Some are really expensive, others are cheap. There are also a bunch of different KINDS of printers. Kind of like going to Kinkos and deciding between dot matrix, B&W laser, colour laser, or full-on photo quality printer. Next, there's the cost breakdown. Pretty much everyone charges a set-up cost per model (ie, per file), plus a cost per volume of the material. So if you print one part, it's set-up+volume. If you print two parts, it's (set-up+volume) + (set-up+volume). But if you edit the model to have two parts in the actual file, it'd be set-up+2xvolume. (if that makes any sense) Finally, there are different materials. You COULD, if you wanted, have it printed in ceramic, or glass, or metal. You could even have it printed in silver, or have it gold plated. Obviously that'd up the cost a lot. ----- I'm using Shapeways. They are about the cheapest printer that I've found, and also do pretty good resolution. Their highest quality prints - "Frosted Ultra Detail" - allow for .3mm wall thickness (about .012"). A step down is "Frosted Detail", which uses the same printer, but at a slightly lower res, and requires a minimum of .6mm wall thickness. It SHOULD let you include pretty fine rivet detail and minimal post-processing. They charge $5 per model for set-up/handling and about $2.50/cm3 for that material. Another step down changes to a different printer and material, "Fine Detail Plastic", but still decent enough for modelling purposes - you'll lose the really fine detail and need a little more smoothing, but for something like drop tanks, it should be good. That's $2.50/per for set up and $3/cm3 for the material. A single pair of brakes in Ultra Detail is $6.63. So that's $5 for the model, and $1.63 in material. If I had ten pairs of brakes in the model, it'd be $21.30 for the lot, or $2.13 per pair. For comparison's sake, that same, single pair in frosted Detail is $6.11, detail plastic is $3.89. (Gold plated is $12.73  |

|