Post by Mofo on Oct 26, 2012 17:03:21 GMT -7

The parts are here, and I've had a preliminary play. A few thoughts...

They smell nice. The print process uses a wax to support the actual printed plastic, so it basically prints a big block of wax with your bits inside. The wax is mostly removed, but there's some residue, which has a nice, coconut smell.

The print process uses a wax to support the actual printed plastic, so it basically prints a big block of wax with your bits inside. The wax is mostly removed, but there's some residue, which has a nice, coconut smell.

It also means you'll need to soak the bits in warm, soapy water to fully clean them. Might have to invest in an ultrasonic cleaner. Not *terrible* to clean, but could be a problem for painting. We'll see.

The plastic isn't as brittle as I'd thought. It's kind of somewhere between resin and clear plastic - slightly flexible, but still feels brittle. Cut a few parts off with a JLC saw, and it felt much like clear plastic. Handle with care, but not with kid gloves - it should be workable.

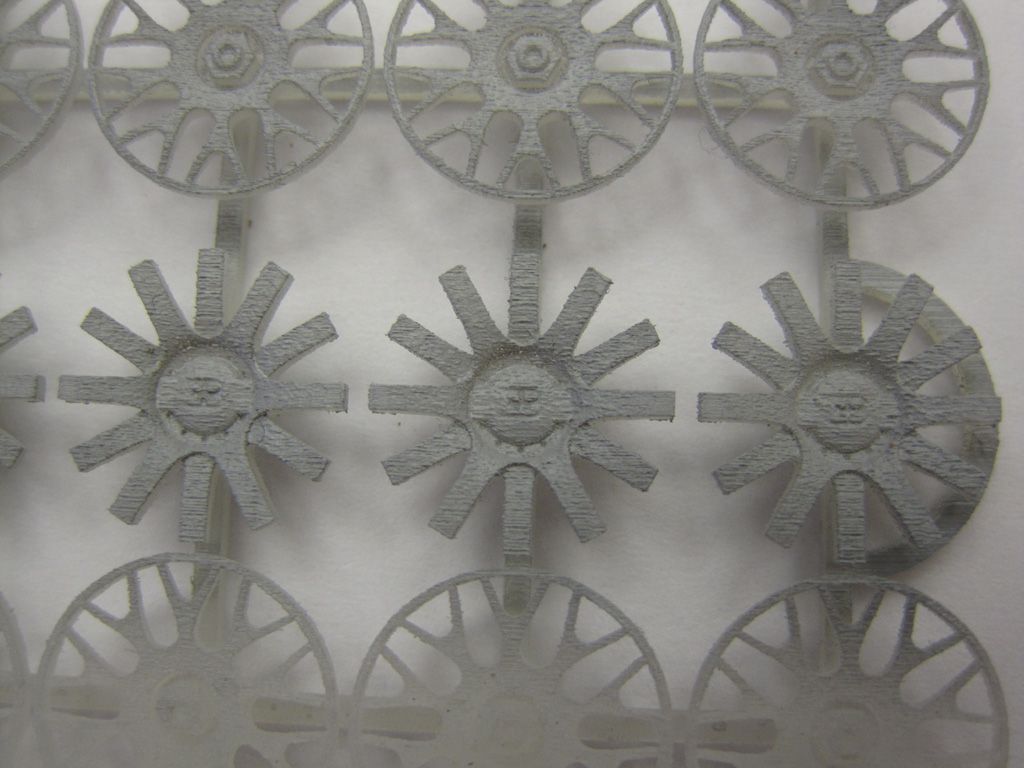

There's more texture than I'd hoped. It'll need quite a bit of cleanup, which means production printing is out. Also: lots of rivet detail is probably a waste. (in fact, any significant detail is probably a waste) I'm thinking, clean masters, then scribe/drill any surface detail.

The baggage pods are about 1mm thick, IIRC, and they feel pretty robust. No real worries handling them at all. Thinner parts are a little more delicate feeling, but not bad.

I built in a clearance for the baggage pod halves, and they've got a satisfyingly snug press fit. I didn't factor in a gap for the doors, and they'll need some clean-up to work. So def. factor in clearance in future.

The parts are tough to photograph, as they're transluscent - clear white on a white background? Not fun to autofocus. I'll try to shoot some primer tomorrow for a better idea how they look.

I'll try to shoot some primer tomorrow for a better idea how they look.

---

Pics! Full gallery here: s21.photobucket.com/albums/b251/IronChefMoFo/parts/3d/prints/

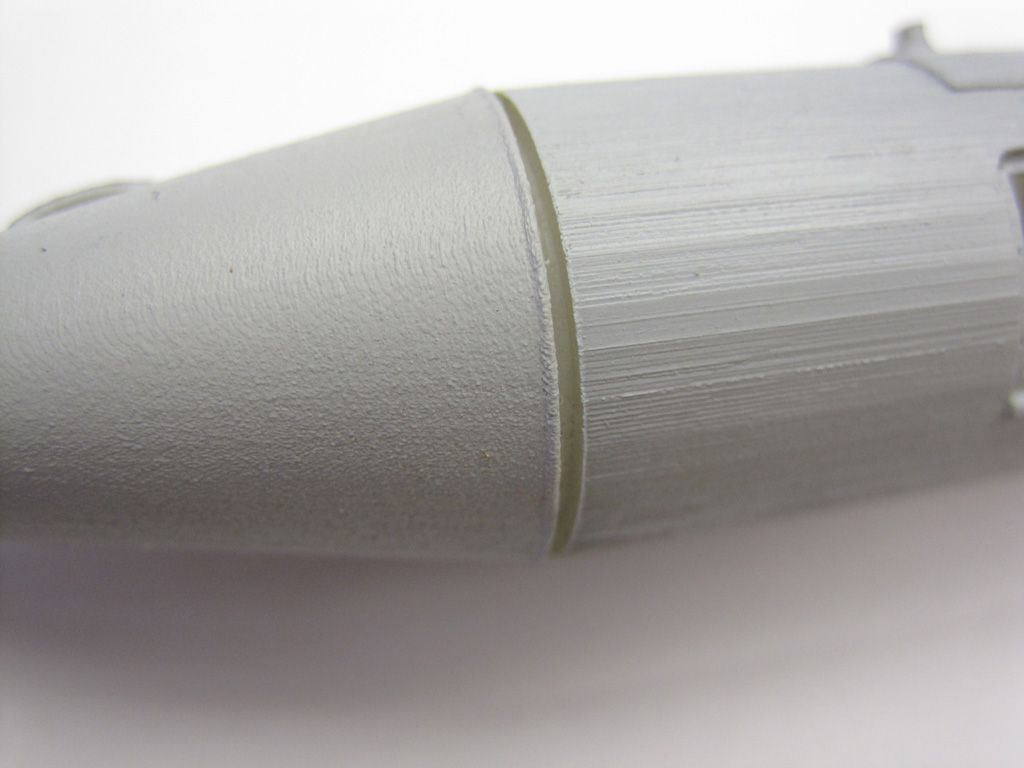

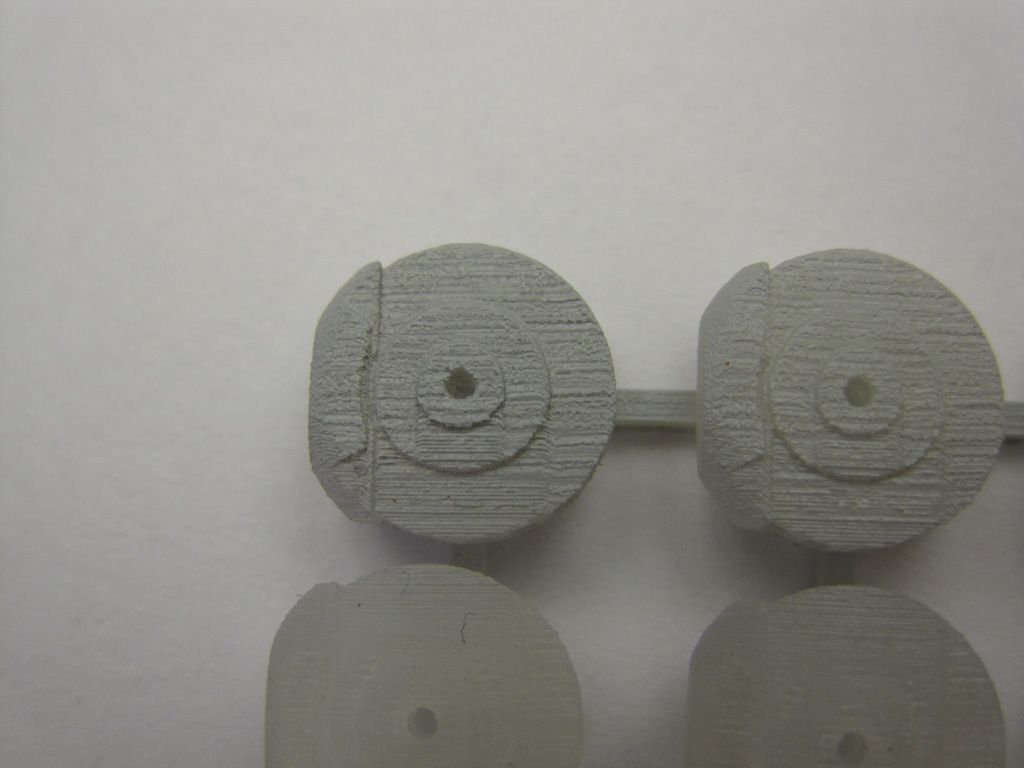

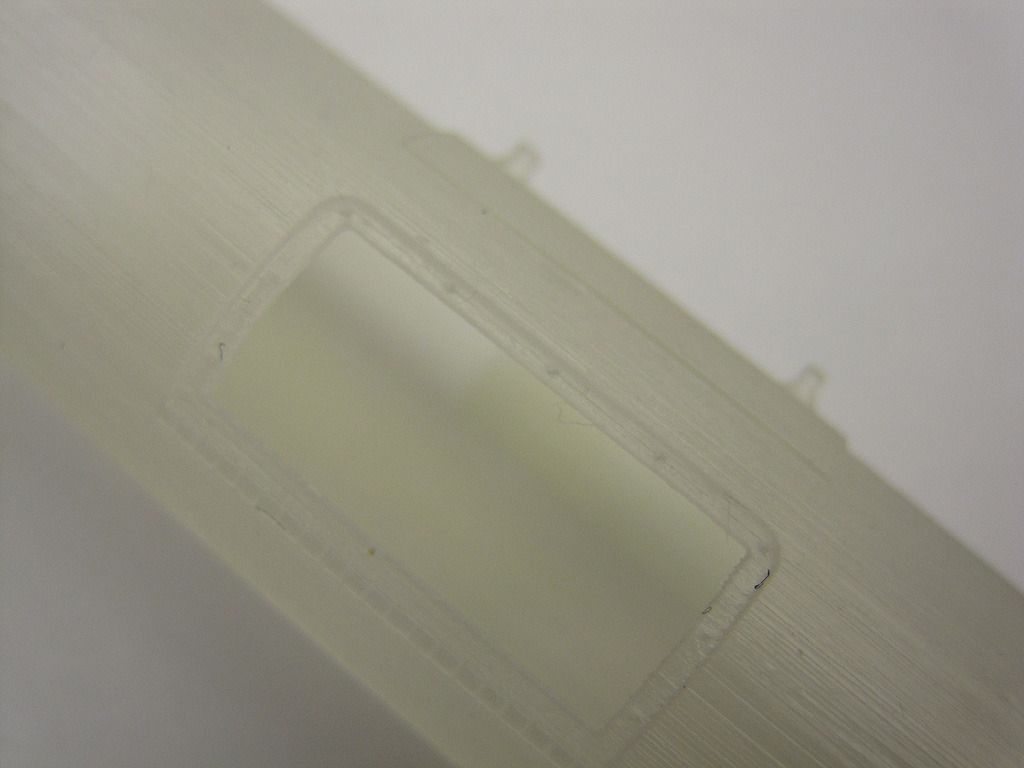

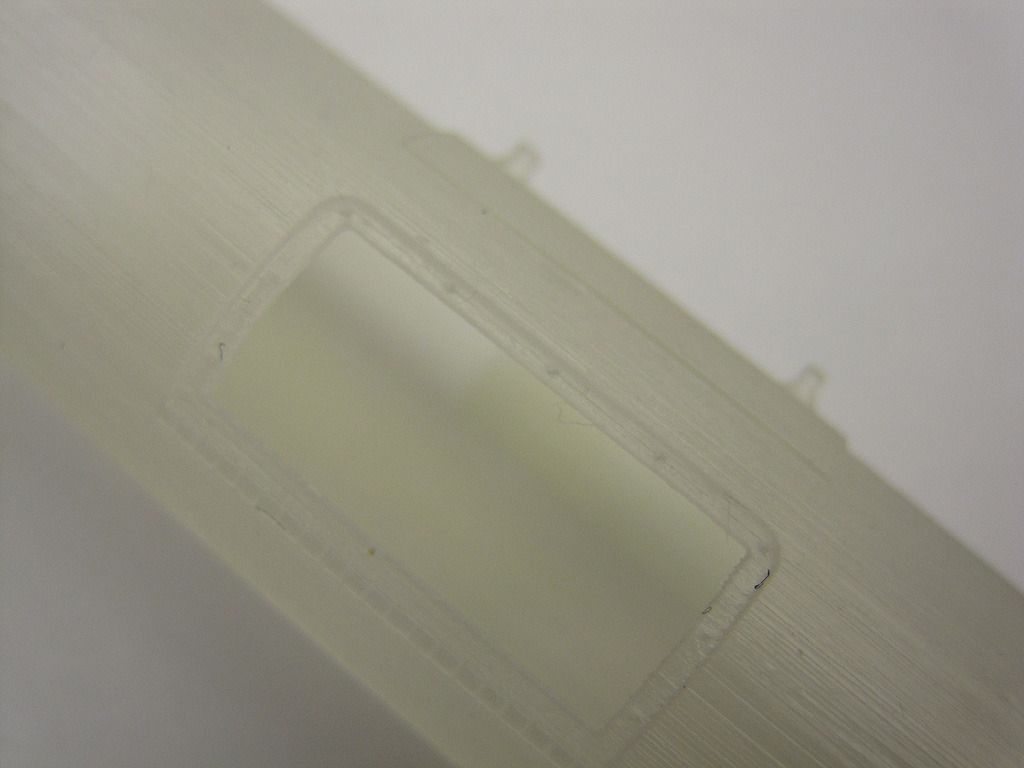

The 1/32 pod. Detail is pretty clear... it's just heavily layered. Couple heavy coats of primer and some sanding and it should be smooth, but it's definitely not usable OOB. The rivet holes are visible, but I don't think they go through. I'll have to drill them out, I guess.

Worth noting: the hinge detail on the print looks like scribed lines between each segment; the original model had gaps. Not a big deal, but an interesting change. Also, the holes only printed on the 1/32 pod; I can't see them on the 1/72 or 1/48 ones.

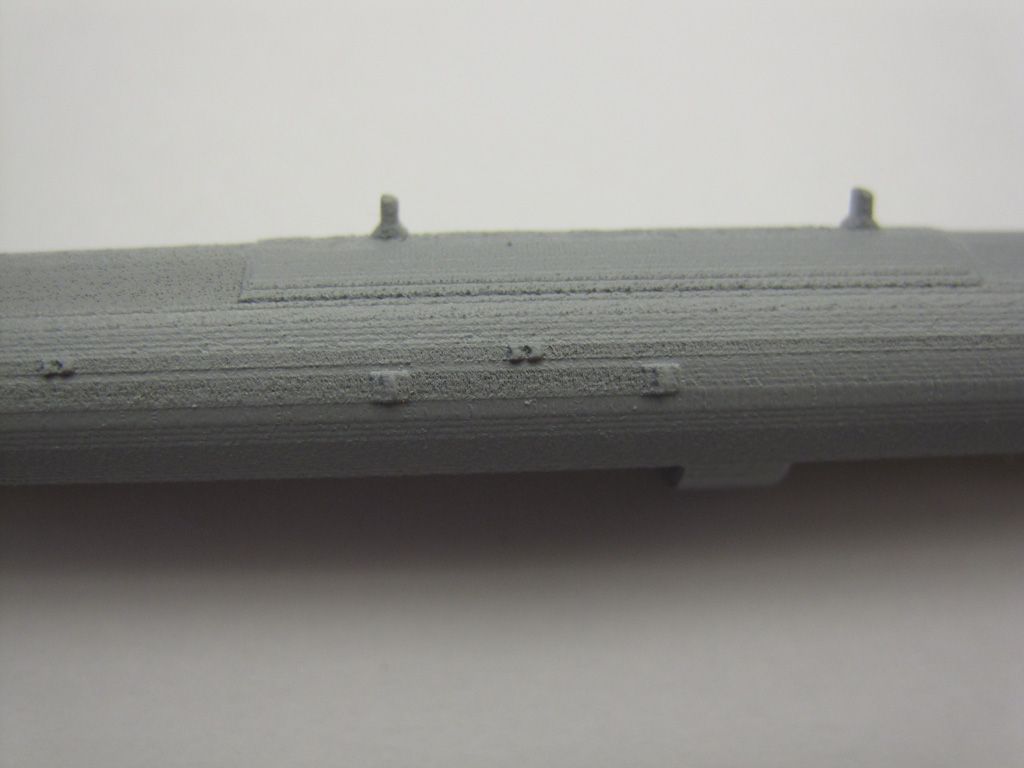

Better view inside the pod, showing the lines. They vary over the part's surface, in depth and pattern. Some areas are pretty light, others are coarser. Guess it had to do with the orientation on the print bed:

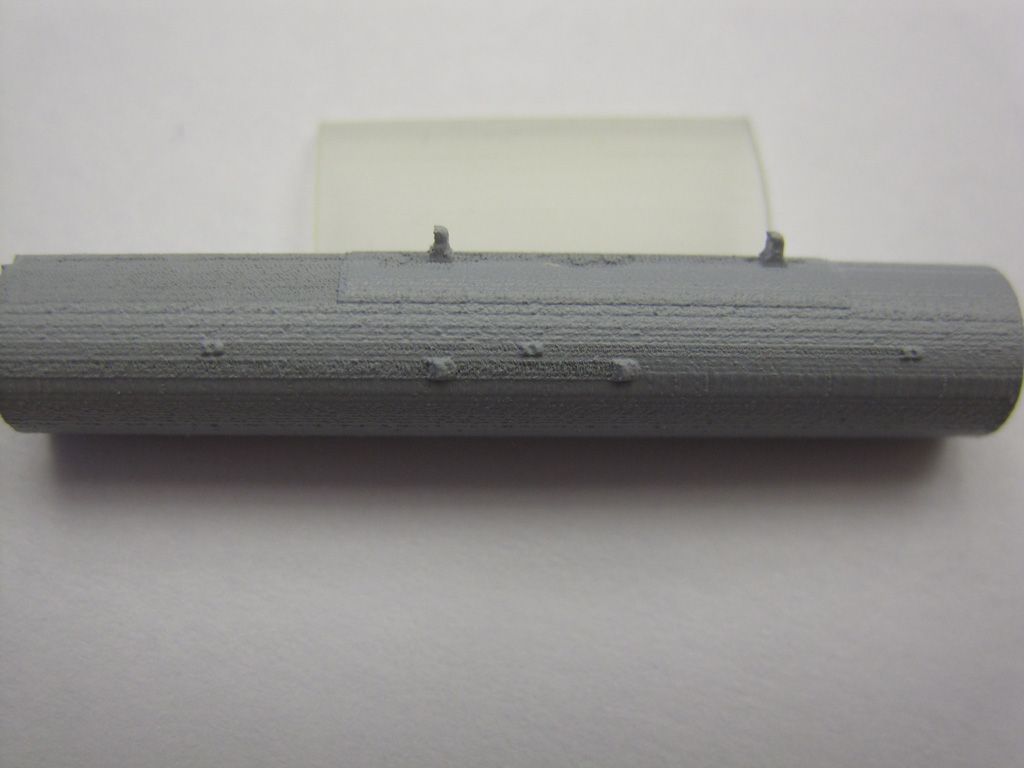

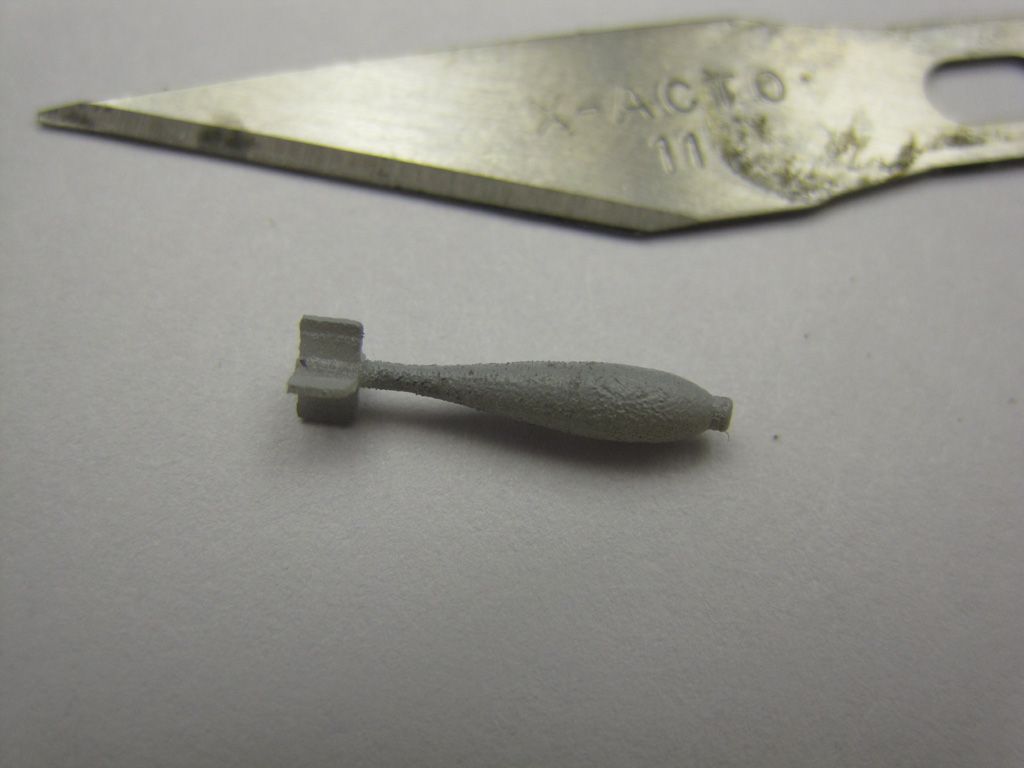

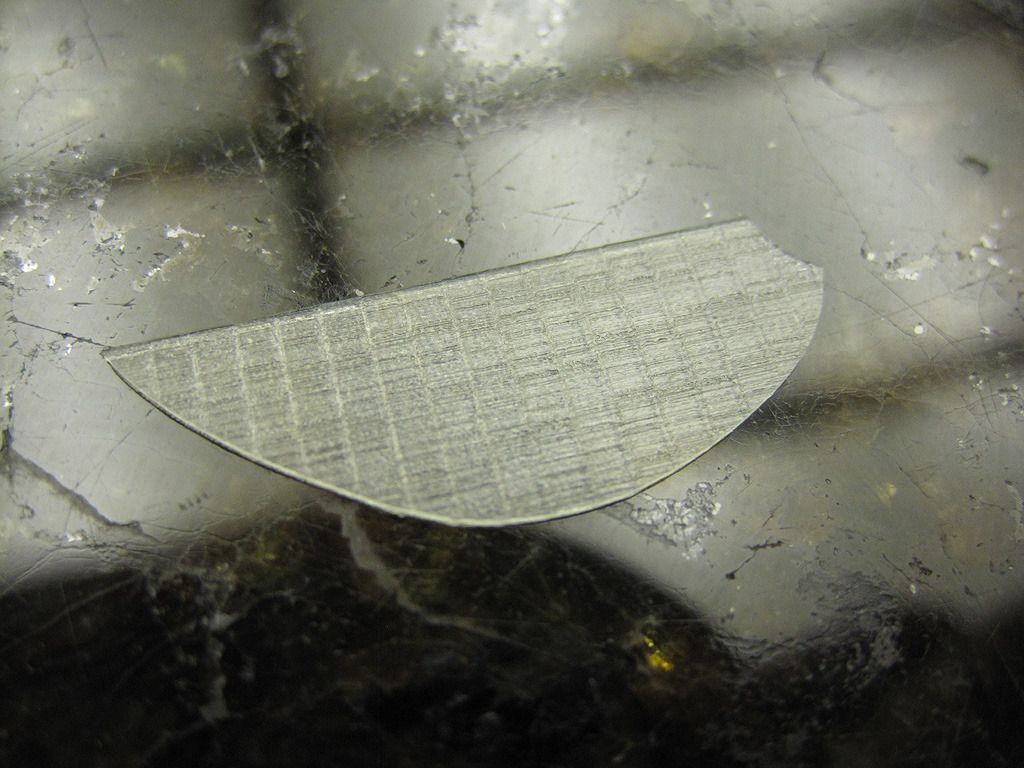

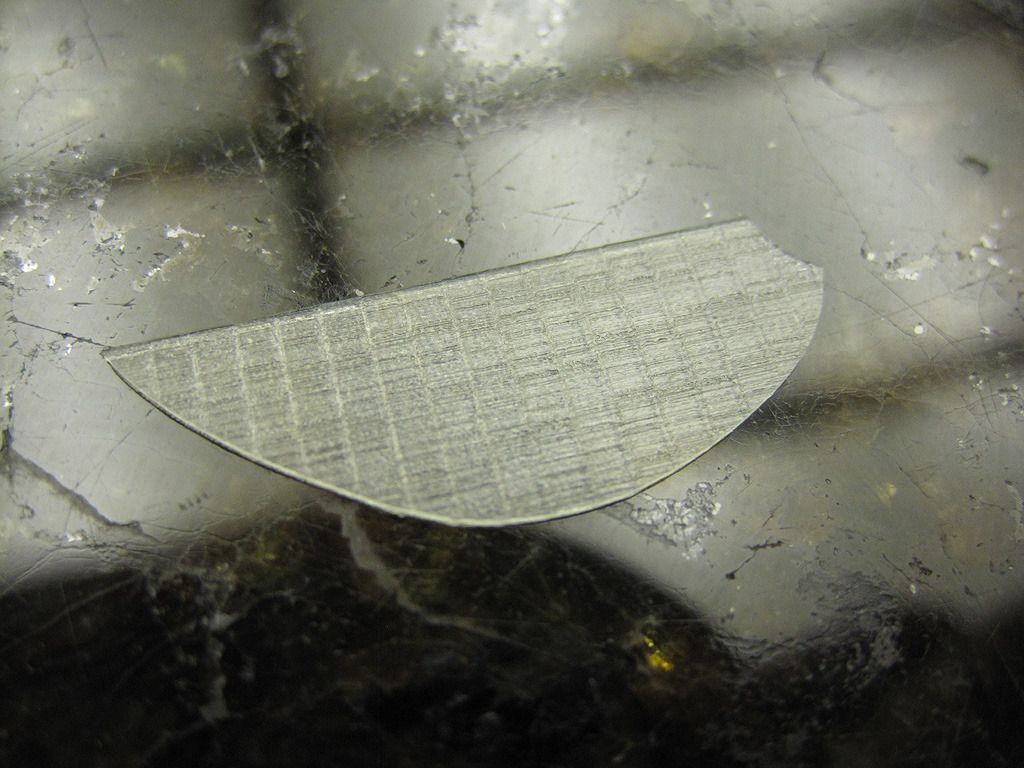

The BDUs have that pattern change in their middles. Again, weird. They're coarser than I'd hoped, fins are a little thick, but hopefully workable. And certainly easier to handle than tiny PE pieces, or something (nice thing about printing everything in situ - you don't have to glue and align parts!)

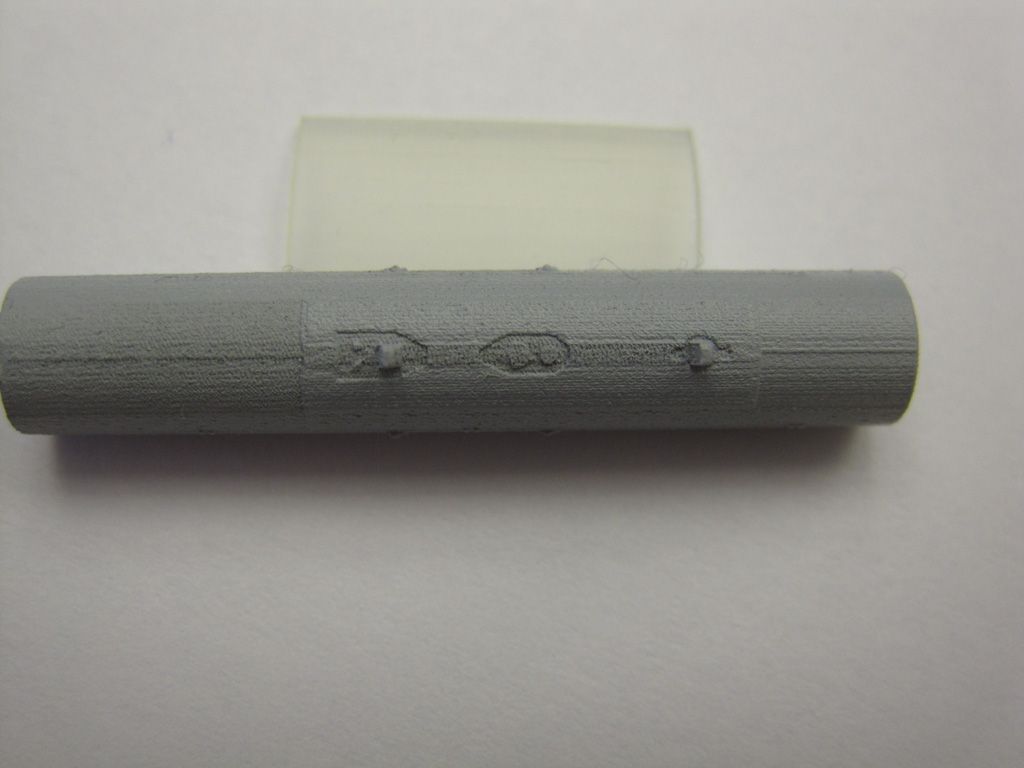

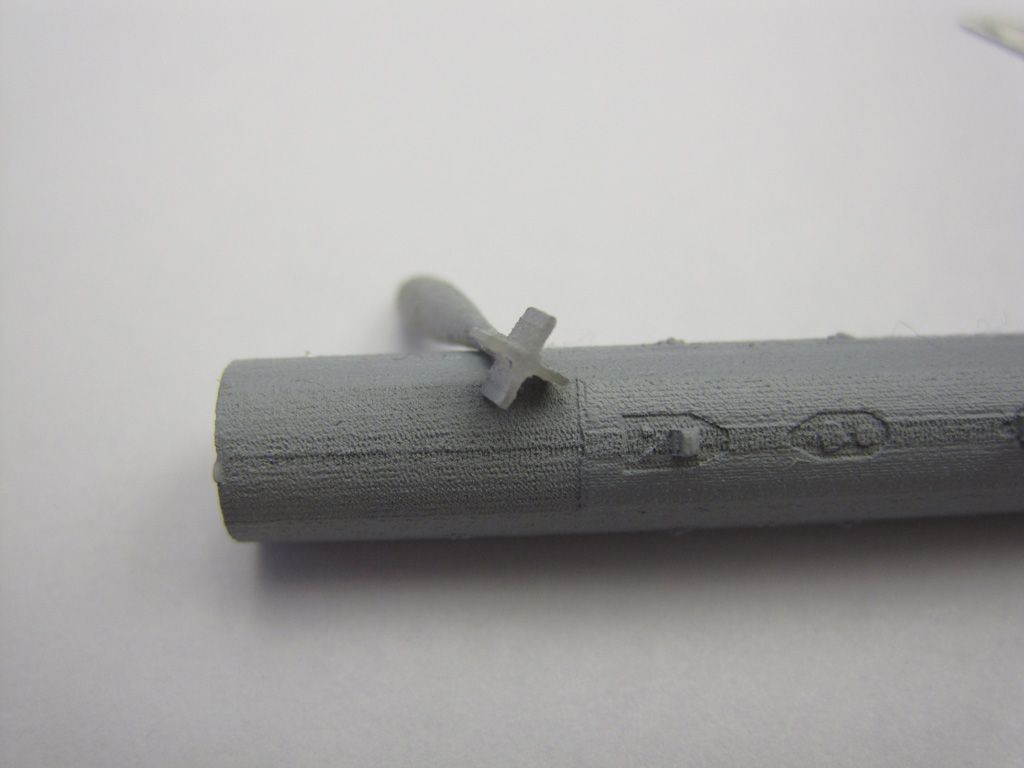

I added a box around the BDUs, to protect them during shipping (everything was well packaged, BTW). Here's part of one of the walls. Not a bad zimmerit texture, actually. I'll do some playing with the scrap plastic to see how it handles.

Generally? I'm pleased, not thrilled. The limitations are still clear. Not really sure if it's worth splashing out many times the price to try another printer; more research is in order.

They smell nice.

The print process uses a wax to support the actual printed plastic, so it basically prints a big block of wax with your bits inside. The wax is mostly removed, but there's some residue, which has a nice, coconut smell.

The print process uses a wax to support the actual printed plastic, so it basically prints a big block of wax with your bits inside. The wax is mostly removed, but there's some residue, which has a nice, coconut smell.It also means you'll need to soak the bits in warm, soapy water to fully clean them. Might have to invest in an ultrasonic cleaner. Not *terrible* to clean, but could be a problem for painting. We'll see.

The plastic isn't as brittle as I'd thought. It's kind of somewhere between resin and clear plastic - slightly flexible, but still feels brittle. Cut a few parts off with a JLC saw, and it felt much like clear plastic. Handle with care, but not with kid gloves - it should be workable.

There's more texture than I'd hoped. It'll need quite a bit of cleanup, which means production printing is out. Also: lots of rivet detail is probably a waste. (in fact, any significant detail is probably a waste) I'm thinking, clean masters, then scribe/drill any surface detail.

The baggage pods are about 1mm thick, IIRC, and they feel pretty robust. No real worries handling them at all. Thinner parts are a little more delicate feeling, but not bad.

I built in a clearance for the baggage pod halves, and they've got a satisfyingly snug press fit. I didn't factor in a gap for the doors, and they'll need some clean-up to work. So def. factor in clearance in future.

The parts are tough to photograph, as they're transluscent - clear white on a white background? Not fun to autofocus.

I'll try to shoot some primer tomorrow for a better idea how they look.

I'll try to shoot some primer tomorrow for a better idea how they look.---

Pics! Full gallery here: s21.photobucket.com/albums/b251/IronChefMoFo/parts/3d/prints/

The 1/32 pod. Detail is pretty clear... it's just heavily layered. Couple heavy coats of primer and some sanding and it should be smooth, but it's definitely not usable OOB. The rivet holes are visible, but I don't think they go through. I'll have to drill them out, I guess.

Worth noting: the hinge detail on the print looks like scribed lines between each segment; the original model had gaps. Not a big deal, but an interesting change. Also, the holes only printed on the 1/32 pod; I can't see them on the 1/72 or 1/48 ones.

Better view inside the pod, showing the lines. They vary over the part's surface, in depth and pattern. Some areas are pretty light, others are coarser. Guess it had to do with the orientation on the print bed:

The BDUs have that pattern change in their middles. Again, weird. They're coarser than I'd hoped, fins are a little thick, but hopefully workable. And certainly easier to handle than tiny PE pieces, or something (nice thing about printing everything in situ - you don't have to glue and align parts!)

I added a box around the BDUs, to protect them during shipping (everything was well packaged, BTW). Here's part of one of the walls. Not a bad zimmerit texture, actually. I'll do some playing with the scrap plastic to see how it handles.

Generally? I'm pleased, not thrilled. The limitations are still clear. Not really sure if it's worth splashing out many times the price to try another printer; more research is in order.