|

|

Post by Mofo on Mar 6, 2014 13:33:18 GMT -7

(since he's probably the most likely to have used them...)  Ever used a biopsy/tissue punch on styrene? I need to make 100+, precisely located holes in some .020" styrene sheet. Drilling is probably out. I'm wondering if a dermal punch would work. Probably just some cheap disposable type. Would they be robust enough to hold up? Are they likely to deform or break? Will I be able to give them a sharp whack to punch through (mallet, maybe? a la Waldron punch) or do they need more of a 'drilling' motion? Do they usually have some way to eject the cores? I've got a leather punch inbound as a backup, but it's a clunkier unit - thicker walls, wider taper - so I'm worried the holes might not be as precise. |

|

|

|

Post by timmay on Mar 8, 2014 18:26:20 GMT -7

I don't think you will get very many decent holes with those units. I got a very close look at one of these when I had a small tumor come up on my arm. One reason they are so sharp is that the blade is very thin and I don't believe they will take kindly too a whack from a hammer. I believe drilling will be the best bet. Use a couple of sacrificial outer pieces That are fairly thick. About .080 should do the trick. I don't know how big of a piece you are making the holes in. Cut four or five pieces, or however many you need, but cut several extras. Cut them all the same size. make all the pieces a little longer in length say about 1/4 of an inch on each end. Stack the said pieces along with the thicker pieces. Clamp tightly and apply some MEK to the ends. A light pass with a brush should do it. Mark the pattern on top and if you have an X-Y table set about drilling the said stack using a block of wood as a backstop. When finished cut off the glued ends and discard the sacrificial pieces, fan out the finished pieces and choose the best. Old school I know, but sometimes the old school is the best school. Hope this helps. Timmay!  |

|

|

|

Post by gnat on Mar 12, 2014 9:20:31 GMT -7

Ditto on that Mike; those punches are dull after about 2 uses and are really only single use. You can buy Forstner bit down to a very small size, they cut a perfectly round hole.

Gnat

|

|

|

|

Post by Mofo on Mar 13, 2014 15:21:43 GMT -7

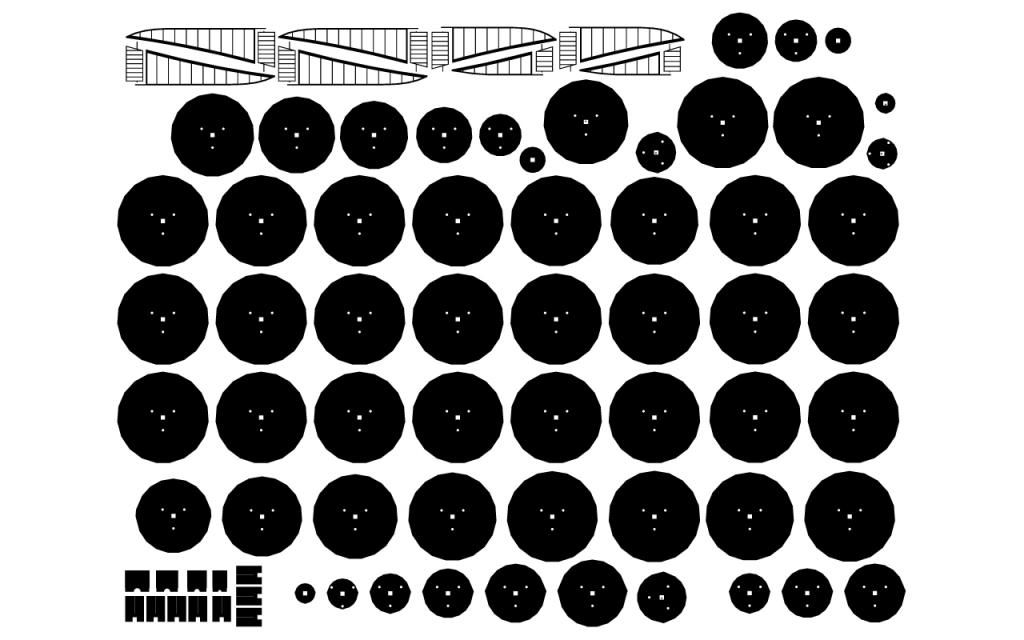

Unfortunately, I don't think a drill is going to work. Here's the template. I've printed it out and will be spray-mounting it on .020" sheet stock to form the actual styrene pieces. They are bulkheads on a central (square tube) spar, with three holes around that to add secondary spars for rigidity. Everything is measured off the centreline and has to be *exact* to keep the alignment. And, since the holes are spaced out from the centre, rather than the edges, it makes stacking impossible (half the bulkheads are different diameters), and jigging it problematic. Unfortunately, as I've got to cut 70 bulkheads, 4x holes per (including the centre spine).  My thinking was, with a punch, I can carefully line it up by eye with the printed template, then whack with a mallet or twist to cut through. I neglected to mark off the centreline of the holes, so precisely locating a drill bit will be tricky. And given the number of holes I have to make, I'd rather not have to meticulously set up each one. Plus, we're talking 4mm diameter holes here (5/32"), so a forstner is almost certainly out anyway. Plus: no drill press, making things even worse. Though that does give me another idea... I've got some 1/8" clear lexan sheet. I could build something like a Waldron punch out of that - glue a .020" spacer in between two sections. Drill my 4mm hole through the lexan, then I can slide each bulkhead template into the slot, line up the markings with the hole, and drill. (basically, imagine a Waldron punch, except instead of using a metal pin to punch through, using a drill bit to drill through) I'd need to source a drill press, though. Originally, I had actually looked into laser cutting, to avoid all this, but it seems that lasers don't really work well on styrene. Plus: co$t. |

|

|

|

Post by Cap'n Wannabe on Mar 14, 2014 14:17:15 GMT -7

|

|

|

|

Post by timmay on Mar 23, 2014 7:10:01 GMT -7

Looks like a Zepplin, Mike. Here in the states we have stores called Harbor Freight. You can find any type of drill press with corresponding price tags. You can also get an X-Y table as well. I bought a bench type model a few years ago for $69.95 US. Don't know if you have anything similar there. Timmay!

|

|

|

|

Post by Dave F on Mar 25, 2014 7:29:47 GMT -7

I got a bench drill press for about £15 a few years back - takes a standard power drill. But that ain't gonna help Mike!

Dremel do one for their tools.

|

|

|

|

Post by Mofo on Mar 26, 2014 8:21:39 GMT -7

I think I'm leaning towards the leather punch as plan A, with a drill press and some sort of alignment jig as plan B. Guess it's time I bought myself a bench drill press anyway.  Oh, and Timmay... shhhhh!  |

|